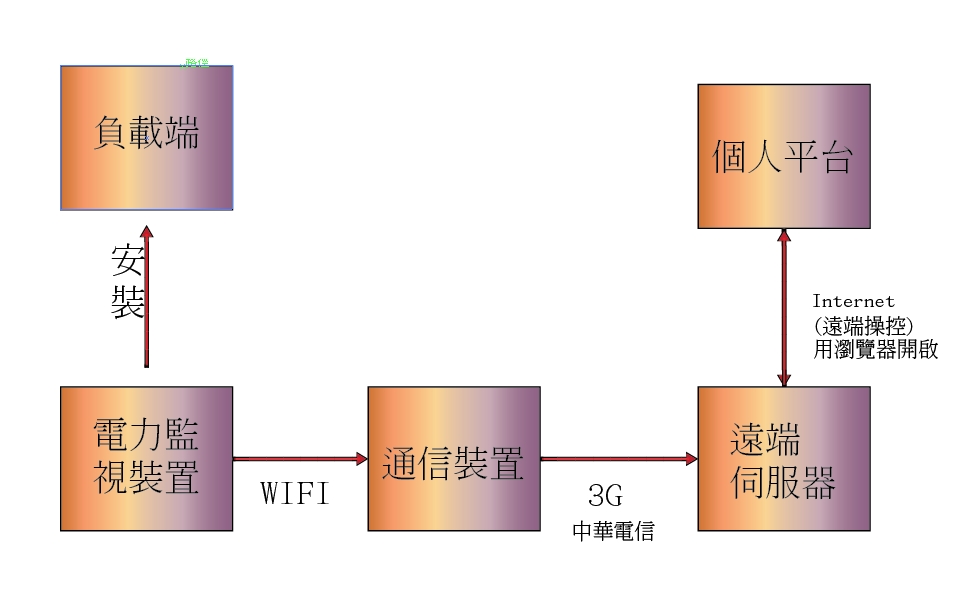

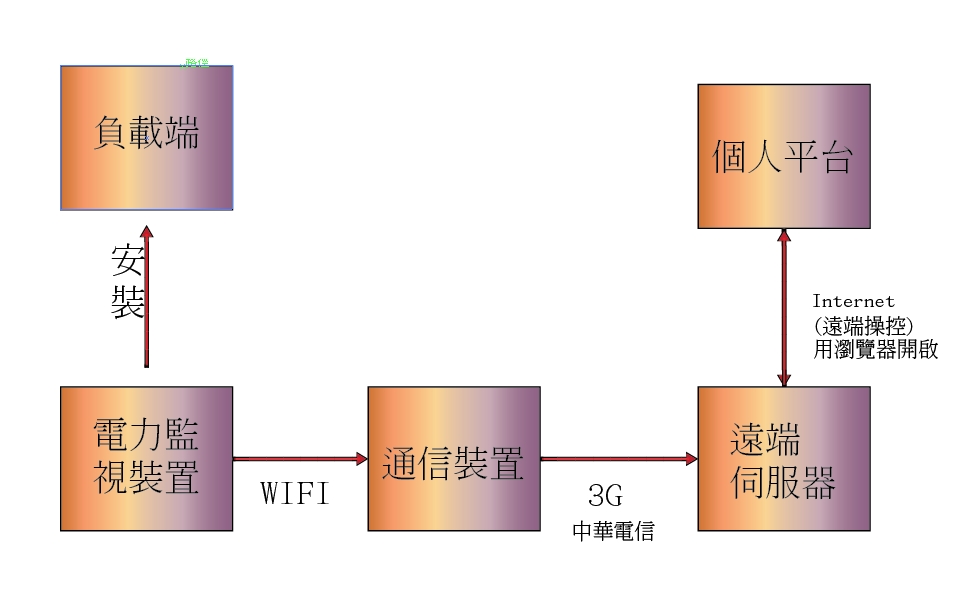

P.Q.C.S. and Entire Factory Circuit Monitoring System Diagra

1.Function

The First Phase

Entire Factory Power Quality Control System

(1).Monitoring high and low voltage currents data and records

(V, I, KW, Var, KVA, Kwh, pf, Hz, and harmonica current etc.)

(2).Web-base Monitoring and search (website + software)

(3).Data/Chart viewing (real-time + history)

(4).Provide comparable data between electrical company and P.Q.C.S. system

The Second Phase

Entire Factory each Current (low voltage) Monitoring

(1).Monitoring low voltage current data and records

(V, I, KW, Var, KVA, Kwh, pf, Hz, and harmonica currents etc.)

(2).Web-base Monitoring and search (website + software)

The Final Phase

Entire Factory each device/equipment (low voltage) Monitoring

(1).Monitoring low voltage current data and records

(V, I, KW, Var, pf, Hz, and Temp. etc.)

(2).Web-base Monitoring and search AMI Smart Meter(High Volt.)

(3).Send emergency alarm message to mobile phone/computer

2.Purpose

(1).Monitor the entire factory each load end of the data and records,analyze whether the presence or absence of the normal operation of each device

(2).Prediction equipment time,before equipment failure,advance preventive measures,reduce unnecessary yield loss

(3).Reduce maintenance costs artificially,monitoring replace human,achieve savings results

3. Schematic diagram http://imgur.com/7jwQIoV